As part of the project, SMS group will provide all key equipment that determines quality, as well as the heating systems and automation technologies.

Fully electric heating systems and high-capacity extrusion press

The systems supplied by SMS group include fully electric heating solutions, consisting of horizontal preheating for billets, intermediate heating before piercing, and final heating before extrusion.

In addition, a next-generation horizontal pipe extrusion press featuring an expansion press and a water-cooling tank will be installed for the extrusion of pre-pierced billets. With this system, Maruichi will increase the extrusion force from 20 meganewtons to 50 meganewtons, significantly expanding the range of stainless steel pipe sizes that can be produced.

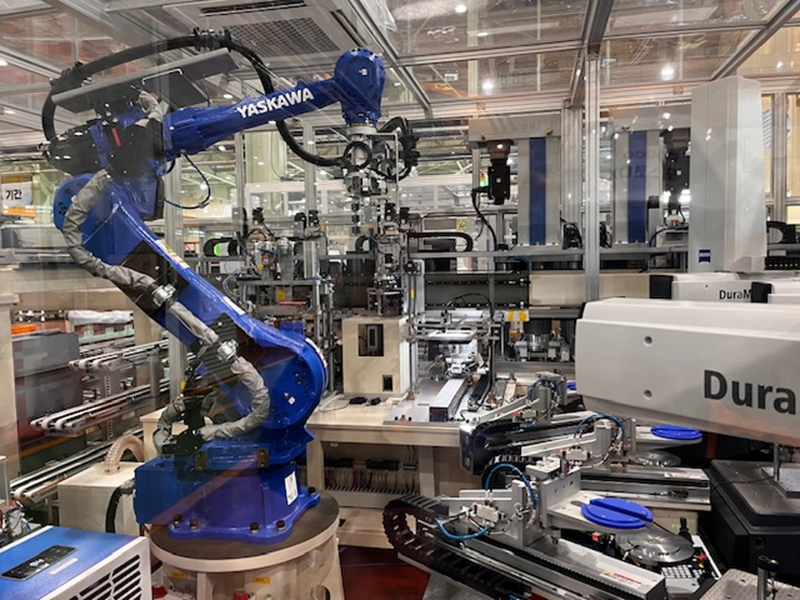

Highly automated production line and smart control system

The new facility will be equipped with a highly automated production system to maintain quality at every stage of the manufacturing process. SMS group’s automation solutions will enhance efficiency, minimize human error, and ensure consistent quality throughout all production steps.

The production line will also be integrated with the MIDIS (Management Information Diagnostic Indicator System) production control system, which allows precise monitoring and control of all processes. MIDIS provides real-time data analysis and process optimization, ensuring uninterrupted operations and full compliance with international quality standards.

Production target for 2027

Construction of the new plant is planned to be completed by the end of 2026, followed by equipment installation. The facility is expected to start production in fiscal year 2027 after obtaining JIS (Japanese Industrial Standards) certification.

Tsunakawa: “Setting a new benchmark in the global steel pipe industry”

Toru Tsunakawa, General Manager of SMS group KK, emphasized that the collaboration sets a new global standard, stating:

“The partnership between SMS group and Maruichi Stainless Tube establishes a new benchmark for the global steel pipe industry. The new stainless steel pipe production, combining advanced technology, precision engineering, and a quality-focused approach, sets new standards in innovation and efficiency. We are proud to play a pioneering role together with Maruichi Stainless Tube in shaping the future of stainless steel pipe manufacturing.”

Comments

No comment yet.