The European Union’s Green Deal is a key strategy aimed at transitioning to a clean-energy-based economy and achieving carbon neutrality by 2050. With its Carbon Border Adjustment Mechanism (CBAM), the EU seeks to ensure compliance with environmental standards and maintain fair competition. The impacts of these measures on the metal casting sector—whose main export market is Europe—and the industry’s preparations are crucial for short- and medium-term projections.

In the metal casting sector, companies with a clear sustainability vision are implementing environmental investments according to strategic plans. Their goals, allocated budgets, completed and upcoming projects have come under the spotlight. Members of the Turkish Foundry Association (TÜDÖKSAD) have initiated value-added investments that will place the Turkish casting industry a step ahead of global competitors. This advantage is expected to be particularly strong in winning new orders over major rivals such as China and India.

Sustainability Stories from the Sector

Oğuz Özmen, CEO of Cevher Group:

“We see sustainability as our vision for the future. At Cevher Alloy Wheels, we are committed to exemplary sustainability practices in the casting sector, treating environmental responsibilities not just as a corporate duty but as a strategic vision. Reducing carbon emissions, recycling waste, using resources efficiently, and integrating innovative technologies form the core of our sustainability approach.”

In 2024, Cevher allocated EUR 150,000 to environmental sustainability goals. The company’s environmental plans are fully strategic, aiming to protect not only today’s resources but also those of the future. These plans are integrated into all company units, focusing on:

-

Carbon Footprint Reduction: Since 2021, electricity-related greenhouse gas emissions have been neutralized with green energy (IREC) certificates.

-

Material Recycling: Chips and scrap wheels from production are remelted; in 2024, 17,226 tons of aluminum waste were reintroduced into production.

-

Energy Efficiency: Certified under ISO 50001, the energy management system optimizes electricity and natural gas consumption, supported by KAIZEN and Lean Six Sigma projects.

-

Waste Management: With a “Non-Hazardous Waste Recovery License,” scrap materials from both internal and external sources are reused in sustainable production.

The company also invests in next-generation clean production technologies, such as a chemical wastewater treatment plant and an EDI process water system in its second plant. Paint consumption has been reduced by 11%, saving resources and lowering hazardous waste output.

Cevher holds several environmental certifications, including:

-

ISO 14001 Environmental Management System

-

ISO 14046 Water Footprint Verification

-

ISO 14064 Greenhouse Gas Emissions Verification

-

ASI (Aluminium Stewardship Initiative) Certification – the first in Turkey’s wheel sector

Beyond production, the company conducts environmental awareness training for employees, applies sustainable supply chain practices, and engages in social responsibility projects. In 2023, 1,106 trees were planted to establish a company grove in Manisa.

Dilek Gündüz, General Manager & Board Member, Erkunt Sanayi:

“In today’s era of accelerated industrialization, focusing solely on economic success in production is not enough; environmental sustainability and occupational safety have become essential components of corporate responsibility. Companies that protect employee health, respect the environment, and use resources efficiently will be the winners of both today and tomorrow.”

Erkunt Sanayi leads this transformation with sector-leading practices by addressing environmental protection and occupational safety through an integrated approach. The ISO 50001 standard is applied for energy management. Erkunt Sanayi Inc. also implements the ISO 50001 standard in energy management. The company measures energy consumption, determines key energy performance indicators, and carries out continuous improvement efforts to increase energy efficiency. As stated in the annual energy report, Kaizen projects that significantly reduce air leaks were implemented, and diesel forklifts were replaced with electric forklifts, reducing diesel consumption. These practices both save energy and positively impact occupational health by lowering employees’ exposure to harmful gases.

Within water efficiency efforts, Erkunt Sanayi develops projects to reduce water consumption and increase recovery systems. Applications for more efficient water use in production processes, treating wastewater for reuse, and rainwater harvesting systems are important parts of the company’s water management strategy. In terms of recycling and waste management, Erkunt Sanayi recovers waste from processes or disposes of it through licensed companies to prevent environmental pollution. Focusing on sustainable production technologies through R&D, Erkunt Sanayi develops innovative solutions that consume less energy and water and reduce carbon emissions. Investments in eco-friendly materials in casting processes, energy recovery systems, and low-emission production techniques contribute to the company’s environmentally focused transformation.

This transformation also serves to create more controlled and safer production environments where employees are exposed to fewer harmful emissions.

Uğur Demirci, Strategic Projects and Procurement Director, Döktaş Dökümcülük:

“Our production processes operate on a minimum waste principle. Approximately 0.3% of our total 2024 investment was allocated to environmental projects. By regularly investing in environmental initiatives such as energy efficiency, emission reduction, and resource optimization, we aim to minimize our environmental impact. Given our sector’s energy-intensive production, using natural resources efficiently, reducing carbon footprint, and implementing circular economy practices are part of our long-term success and responsibility approach.”

Steps implemented to achieve these goals include:

-

Energy and environmental management systems: We hold ISO 14001 Environmental Management System and ISO 50001 Energy Management System certifications, effectively applying these systems to develop environmental and energy efficiency projects.

-

We operate on a minimum waste principle in production, increasing the recycling rate of raw materials used in our foundries to reduce our environmental impact.

-

All electricity used in production facilities comes from renewable energy sources, minimizing carbon emissions.

-

Key environmental investments at Döktaş include energy efficiency projects, carbon emission reduction projects, and production optimization and waste management projects.

Ali Esat Kutmangil, CEO, Kutes Metal:

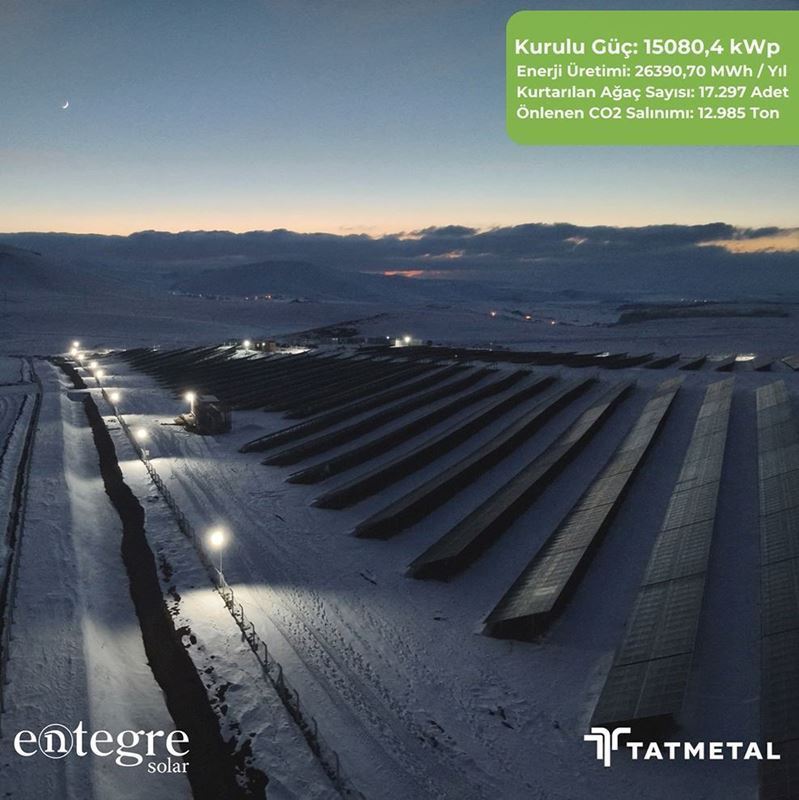

“We invested 75% of our revenue in green energy. As Kutes Metal, we aim to achieve net zero Scope 1 and 2 carbon emissions within the next five years. Our solar energy investment was one of the most important steps toward this goal. In the coming years, we will continue energy investments to produce more green energy than we need, creating a positive impact under Scope 1 and 2.”

In 2018, filtration systems meeting European standards were installed in the facilities. In 2023, a zero-waste certificate was obtained, and as of 2024, electric forklifts are in use. Efficiency investments and new technologies to reduce the carbon footprint continue to be pursued and researched.

Arda Çetin, Deputy General Manager, Ekstrametal:

“Environmental sustainability is always among our annual company goals. With the CBAM process, these goals are shaped within the framework of regulatory compliance. Being one of the few companies in the sector under CBAM, establishing our ISO 14064 corporate carbon footprint calculations and the necessary infrastructure became a priority. We believe that improvements must be supported by data. We think it is not correct to make investment decisions without setting up systems capable of producing accurate data. While many companies prioritized solar panel investments, we established these systems, analyzed our data, and identified that our largest emission sources are supply chain emissions classified as ‘Scope 3.’ Therefore, our primary focus is on roadmaps to reduce these emissions.”

Companies’ starting point should be their own corporate carbon footprint. Investments focusing on waste reduction and raw material recycling, such as in Döküm Termal reclamation, have been made. However, during the CBAM reporting process, it was seen that every company planning investments must start from its own corporate carbon footprint, as unexpected results may occur. Therefore, establishing accurate data flows and analyzing them to define the right actions is critical.

Ahmet Henden, Plant Manager, EKU Brake and Casting:

“We allocate at least 1% of our annual revenue to environmental investments. EKU Brake and Casting is a company that includes environmental sustainability among its strategic planning goals. Our environmental sustainability projects for 2030 have been prepared.”

EKU Brake and Casting summarizes its environmental projects and outputs as follows:

-

In 2024, a EUR 600,000 transition from solvent-based to water-based paint systems was implemented, reducing contaminated waste from 25 tons/year to 8 tons/year.

-

Thousands of tons of process-generated waste sand are partially reused through regeneration. A EUR 1,000,000 regeneration investment is planned for 2026–2027; once completed, annual waste sand will decrease from 10,000 tons to 3,500 tons.

-

For water consumption, a EUR 40,000 water treatment plant project is planned for 2026, expected to provide 4,000 tons of water annually for production processes.

-

VAP projects implemented in 2023 with a EUR 50,000 budget saved 400,000 kW of energy annually.

Nilay Işıklar, Sustainability and Energy Manager, Kalkancı:

“At Kalkancı, our share of revenue allocated to environmental investments has increased each year. In 2024, this ratio was approximately 2%. Increasing our sustainability index and reducing our corporate carbon footprint for climate resilience are part of our long-term goals toward 2030. According to the Science-Based Targets for the 1.5°C climate scenario, based on 2021, we aim to reduce Scope 1 and 2 emissions by 42% by 2030, and we have been pursuing sustainability efforts since 2022 to enhance climate resilience.”

A CDP declaration raised the rating from C to B; for water, the rating was C. Corporate carbon footprint has been calculated since 2021. Scope 2 emissions are offset via IREC certificates directed to RES and GES producing electricity from green energy. Monthly water consumption is tracked according to KPIs based on the net casting weight of produced items.

All these efforts are prioritized within ESG (Environmental, Social, Governance) and sustainable development goals, conducted under a double materiality principle defined with stakeholder and employee participation. In the highest-priority issues, worker health and safety ranks first, followed by climate, emissions, and energy management. Risk management, waste management, and water management priorities are strengthened through long-term compliance with legal regulations and integration of ISO 14001 Environmental Management System.

Source: Ekonomim

Comments

No comment yet.