As part of its strategic collaboration with SMS group, the company has commissioned the integrated strip guiding control system, X-Pact® Centerline Control.

Salzgitter, which has maintained a close partnership with SMS group since 1963, uses this collaboration to periodically upgrade its plant with the latest technologies. Completed in March 2025, this latest project stands out as the most important component of a comprehensive technology package ordered from SMS a year earlier.

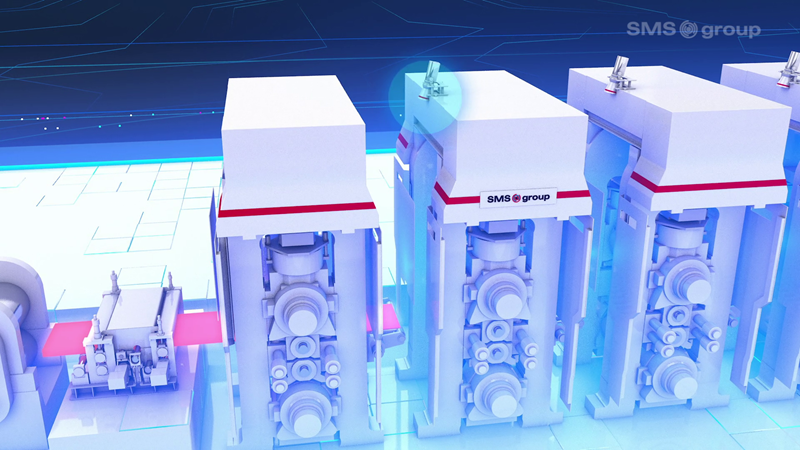

The new X-Pact® Centerline Control system automatically detects and corrects lateral deviations of strips using intelligent cameras. These industrial cameras, capable of operating reliably under challenging production conditions, make real-time adjustments to minimize production issues such as double-rolled edges, torn tail ends, and misalignment.

Through this system, Salzgitter Flachstahl aims to improve rolling stability and strip quality while reducing unplanned stoppages and manual interventions. The fully automated system enhances production efficiency and delivers significant improvements in product quality.

Quality improvements include homogeneous coiling and thickness, low internal stresses, enhanced surface quality, and consistent material properties. These factors increase the processability of the final products and contribute to high performance in Salzgitter’s production processes.

Customer feedback has shown that the solutions provided by SMS group deliver outstanding results. This successful milestone in the collaboration is seen as a reflection of the long-term partnership and innovation-focused vision between the companies.

Salzgitter’s decision to continue working with SMS group is reinforced by SMS’s technological leadership, ability to provide customized solutions, and strong focus on sustainability and digitalization.

Comments

No comment yet.