Through this move in robotic automation, the company aims to increase manufacturing efficiency and strengthen its global competitiveness.

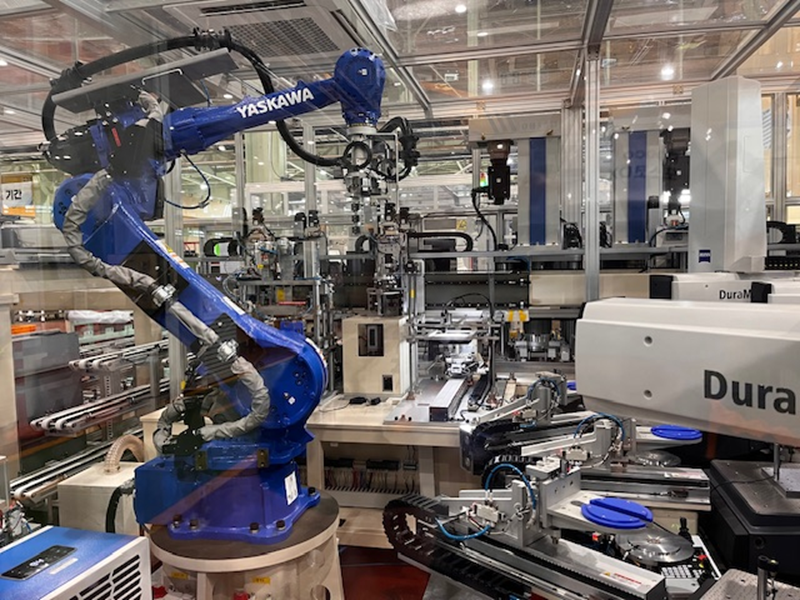

On January 14, a trilateral business agreement was signed at POSCO Mobility Solutions’ Cheonan plant. The ceremony was attended by POSCO DX President Shim Min suk, POSCO Mobility Solutions President Kim Sang gyun, Yaskawa Electric Korea President Yamada Seigo, along with several business partners. Under the agreement, POSCO Mobility Solutions plans to gradually integrate Yaskawa robots into its production lines. These robots transport motor housings to quality inspection measurement equipment and automatically sort inspected products according to quality grades.

It was announced that the robots will be deployed not only at the Cheonan and Pohang facilities, but also at the company’s plants in Poland, Mexico, and India. POSCO Mobility Solutions and POSCO DX had previously introduced these robots on a pilot basis at the Pohang facility last year, achieving successful results. The company stated that the new cooperation will improve production safety, maximize efficiency, and establish a strong foundation for future cost competitiveness.

As part of the cooperation, POSCO Mobility Solutions will define the required robot specifications for its production lines. POSCO DX will design a robot automation layout aligned with existing facility structures and production systems, and will build the entire automation infrastructure. Yaskawa will supply highly precise and optimized robots and provide technical support, including after sales services.

The drive motor cores produced by POSCO Mobility Solutions are key components of electric and hybrid vehicles. These parts convert electricity from the battery into mechanical energy that drives the wheels, enabling vehicle movement. The company supplies these critical components to leading global automakers such as Hyundai Motor Company, Tesla, and Stellantis. Yaskawa, through its expertise in robotics technology based on motion control systems, offers a significant competitive advantage in high speed and high precision manufacturing processes.

In a statement from POSCO Group, the company emphasized that it aims to accelerate the adoption of robotic automation across capital intensive industrial facilities such as steel and battery plants. The cooperation with Yaskawa was also highlighted as being of major importance for the development of physical artificial intelligence based robotic technologies. The group aims to expand these robotic automation technologies not only within its own factories but also across external industrial facilities.

Comments

No comment yet.