Taiwan-based China Steel Corporation has modernized its subsidiary Zhonglong's No. 1 blast furnace, transforming it into an AI-supported production facility. The project, which cost a total of CNY 7.8 billion (EUR 1.014 billion), significantly improved the company's technology and engineering infrastructure.

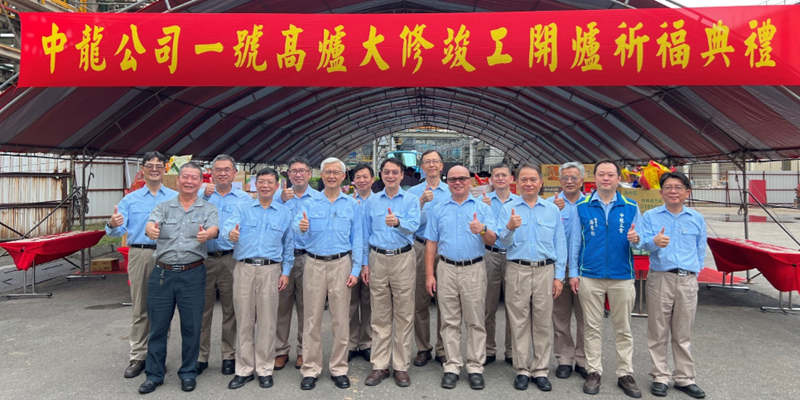

Following the completion of the renovation work, an opening ceremony was held on July 22. Company officials stated that this project represents a new milestone and benchmark for Taiwan's steel industry, both nationally and internationally.

Huang Jianzhi, Chairman of the Board of Directors of China Steel (2002), stated that Zhonglong is one of the most important members of the China Steel group and the only integrated steel plant in Taiwan with both blast furnaces and electric furnaces. He noted that by leveraging the advantages of both melting methods, they have developed the country's first hybrid process technology, enabling high production flexibility and elasticity. The renovated No. 1 blast furnace has been in operation for over 15 years. With a cumulative unit output of 11,000 tons per cubic meter, it ranks third among the group's blast furnace renovation operations and demonstrates strong performance.

This furnace renovation project, considered a major achievement, was planned and executed entirely by the China Steel team for the first time. This resulted in significant advances in engineering design, procurement, manufacturing, construction, and installation capabilities. In addition, China Steel's superior gas recovery system TGRS (Top Gas Recovery System) was integrated into the project, increasing equipment automation, computerization, and the use of artificial intelligence. This reduced production costs while significantly reducing greenhouse gas emissions and promoting environmental sustainability.

China Steel General Director Chen Shoudao emphasized that maintaining the copper cooling wall operation without disruption during the 15-year period of the first generation of the No. 1 blast furnace is a world-class achievement. He expressed his expectations that the second-generation blast furnace, through the renovation, will adopt advanced technology, strengthen smart production, and enhance production competitiveness.

One of the innovative methods used in the project was cutting the remaining chips with a diamond wire saw without changing the furnace shell. This method, which was applied for the first time by the China Steel Group, is noteworthy. The wire saw cutting technology was continuously developed under narrow and unfavorable conditions. Approximately 1,000 support personnel were involved in the 151-day construction process. Continuous progress review meetings, work coordination, industrial safety, and environmental inspections were conducted to prioritize occupational health and safety.

Lu Shaorong, Chairman of the Zhonglong Board of Directors, stated that this high furnace renovation project reflects the group's “two axes and three transformations” business development strategy. He also mentioned that the furnace had entered the high-pressure testing phase prior to its opening, with traversing and lining operations ongoing. He emphasized that despite the challenges posed by the high temperatures of summer, the workers maintained a high level of concentration throughout the process.

Zhonglong Production Vice President Hong Zhengxiong stated that the renovation actively contributed to digital transformation, energy savings, and carbon reduction. He noted that advanced technology systems such as smart steel production, smart rolling, and energy management platforms are being implemented throughout the factory, in addition to the smart high furnace.

Hong Zhengxiong stated that the renovation fully embodies China Steel's spirit of “teamwork, entrepreneurship, resilience, and innovation.” He announced that China Steel has fully embraced its digital transformation and improvement process, laying a solid foundation for sustainable operations over the next 100 years. By stepping into a new era of production focused on artificial intelligence and big data, China Steel has set a new standard for Taiwan's steel industry on the international stage.

Comments

No comment yet.