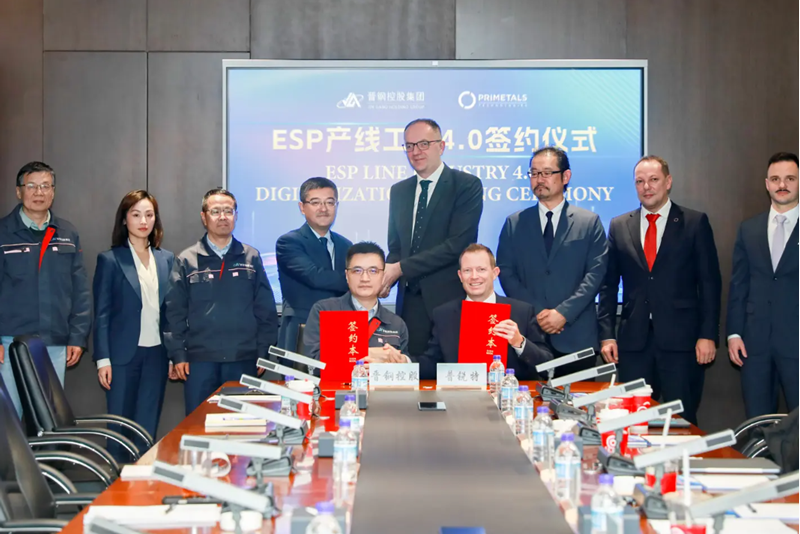

The Industry 4.0 based solution, agreed in December 2025, aims to reduce downtime and increase production efficiency, with the project expected to set a new benchmark for China’s steel industry.

According to a statement released in London on February 3, 2026, the agreement covers advanced digital systems specifically developed for the Arvedi ESP line to be installed at the company’s site in Jincheng, Shanxi province. The scope includes Through Process Quality Control, the Asset Lifecycle Expert system and the ESP Planner.

The solutions are designed to enhance plant reliability, minimize unplanned stoppages and improve overall efficiency through precise quality monitoring, predictive maintenance and flexible production planning. Supported by advanced analytics and a centralized control infrastructure, the system is expected to help Jingang maintain high quality standards in a sustainable manner.

Li Qiang, chairman of Shanxi Jingang New Material Technology, emphasized that the cooperation with Primetals Technologies plays a key role in the company’s transformation and modernization process. He stated that Jingang is steadily advancing toward its goals of premium products, efficient management, intelligent control and green production, adding that the Arvedi ESP line stands at the core of the company’s transformation strategy.

With the ALEX solution, real time asset monitoring will be enabled, while actionable recommendations will be provided for maintenance and operational processes. The TPQC system will continuously track product quality throughout the production process, supporting operators and management with data driven insights. Meanwhile, the ESP Planner will simplify production management by generating detailed production schedules based on orders received from higher level systems.

Tomislav Koledic, chief executive officer of Primetals Technologies China, stated that the digitalization solution will support Shanxi Jingang’s high end product strategy and emphasized that the project is intended to become a reference point for the Chinese steel sector. He added that cooperation in the field of green and intelligent production will continue.

Shanxi Jingang had previously signed a contract with Primetals Technologies in September 2025 for the installation of a fully endless Arvedi ESP line. The line will have the capability to produce endless hot rolled coil in thicknesses ranging from 0.7 to 12.7 millimeters and will feature innovative technologies supporting a wide range of special steel grades, including electrical steel, deep drawing steel and hot forming steel.

Production of the first slab is scheduled for the first quarter of 2027. Powered by renewable energy, Arvedi ESP technology is the only officially certified system capable of delivering carbon neutral thin slab casting and rolling with zero CO₂ emissions. It also stands out as the most energy efficient process for the production of high quality eHRC.

Comments

No comment yet.