According to Alexander Shevelev, CEO of Severstal, some steelmakers may be forced to halt operations due to unprofitability. In an interview with Rossiya 24 during the St. Petersburg International Economic Forum (SPIEF), Shevelev noted that such shutdowns could help ease the current oversupply on the domestic market.

Domestic steel consumption is projected to decline by about 10% this year, dropping to 39 million tonnes. Shevelev emphasized that the contraction is comparable to the total annual demand of an entire industry sector. Despite the market downturn, Severstal plans to maintain its key investment commitments while possibly revising some smaller projects. The company’s 2028 strategy focuses on lowering production costs and boosting output. By 2028, pig iron production is expected to rise by 400,000 tonnes to 11.7 million tonnes, while crude steel output is set to grow by 500,000 tonnes to 11.8 million tonnes. Sales of steel products are forecast to increase by nearly 25% to 13.3 million tonnes.

Meanwhile, oversupply continues to drag down steel prices in Russia, which remain at multi-year lows despite rising production expenses. According to industry agency Metals & Mining Intelligence (MMI), hot-rolled coil prices fell 13% in the first quarter of 2025, averaging 59,500 rubles per tonne. MMI forecasts an 8% year-on-year decline in average steel prices this year, to around 61,625 rubles per tonne.

Prior to the imposition of Western sanctions, Russia’s steel industry was heavily export-oriented, with about 40–45% of production shipped abroad, according to the Ministry of Industry and Trade. However, Shevelev pointed out that with the ruble trading at 78.75 to the U.S. dollar (as of June 24), Russian steel products are struggling to remain competitive globally.

Steel exports from Russia dropped by 8% in 2024 to 20 million tonnes, said Russian Steel Association President Alexey Sentyurin earlier this year. While companies are attempting to enter new markets such as South Africa, logistical and infrastructure challenges are proving to be major hurdles. Still, the association expects a modest export rebound in 2025, with volumes increasing by 2.5% to 20.5 million tonnes.

Steel production within Russia is also declining. Between January and May 2025, crude steel output fell 5% year-on-year to 29.1 million tonnes, according to analytics firm Chermet Corporation. Rolled product output declined 6% to 25.1 million tonnes, while pig iron production remained flat at 21.7 million tonnes.

Yaroslav Kabakov, Director of Strategy at Finam, noted that the most vulnerable producers are those with the highest production costs, such as MMK, Mechel, and small electric arc furnace (EAF) plants. While larger players are striving to cut costs and maintain output, oversupply, estimated at up to 30% of the domestic market, poses profitability risks even for major mills.

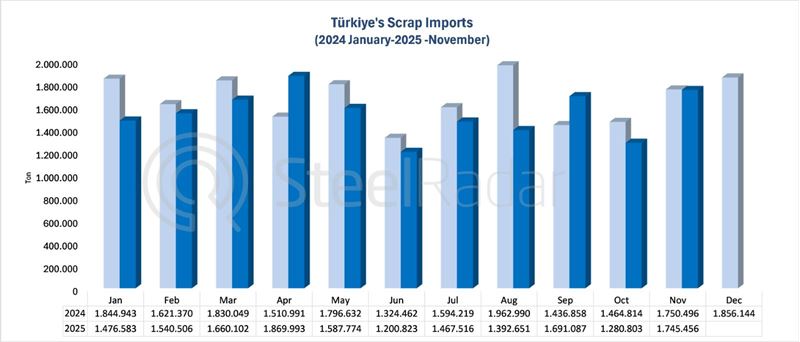

Industrial expert Maksim Khudalov added that rising scrap prices and weak demand for finished steel are eroding profit margins at EAF plants. However, he sees a possible silver lining: a weaker ruble could open up "export windows" for an additional 3–4 million tonnes of steel. Despite Russia’s lower production costs compared to Europe, the U.S., and China, Khudalov warned that Chinese exporters benefit from cheap credit, giving them a significant competitive edge in global markets.

As Russia’s steelmakers battle on multiple fronts, from domestic oversupply to squeezed export potential, the industry’s resilience will depend on its ability to adapt investment strategies, reduce costs, and seize export opportunities in an increasingly competitive landscape.

Comments

No comment yet.