As part of the project, the existing 130-ton No. 1 AOD converter was refurbished, while a new 130-ton No. 2 AOD converter was commissioned. The investment has significantly improved production efficiency, operational flexibility, and operator safety.

The modernization also included the integration of state-of-the-art primary and secondary dust removal systems, as well as waste heat recovery technology. This ensures that the melting shop meets current emission and efficiency standards. With the commissioning of the second AOD converter, Aperam gains greater flexibility for optimized process times and the production of more advanced steel grades. The new converter also allows the use of more cost effective raw materials, contributing to optimized production costs.

Both converters were equipped by Primetals Technologies with the patented Vaicon Autofix automatic AOD converter suspension system. In conventional systems, locking elements connecting the converter vessel to the trunnion ring are operated manually. The Vaicon Autofix eliminates manual intervention during vessel changes, enhancing safety. The system reduces changeover times to less than one hour, increasing plant availability. Additionally, the installed Vaicon Damper vibration reduction system cuts vibrations caused by strong vessel movements by over 50%, minimizing equipment and foundation wear.

For the new No. 2 AOD converter, the waste heat recovery–ready system cools hot exhaust gases from the converter through a two stage heat exchanger. The recovered thermal energy can be used as hot water and holds potential for future industrial applications such as electricity generation or district heating. The system contributes to reduced carbon emissions, supporting the company’s goals for sustainable steel and alloy production.

Sofie Vantilt, Plant Manager at Aperam Genk, noted that the completion of the investment marks the beginning of a new era for the plant. She emphasized that with the second AOD converter and advanced environmental technologies, the plant can operate with greater flexibility, produce more sophisticated steel grades, and further reduce its environmental footprint.

The melting shop was also equipped with a comprehensive automation solution, including Level 1 basic automation, Level 2 process automation and optimization, and the Asset Lifecycle Expert (ALEX) condition monitoring system. The AOD optimization system, based on hybrid process models and dynamic control algorithms, enhances efficiency and metallurgical precision in stainless steel production. The web based ALEX user interface provides centralized, actionable data on plant conditions, supporting rapid and informed decision making. Aperam has also signed a service agreement to ensure the condition monitoring system continues to operate according to current needs.

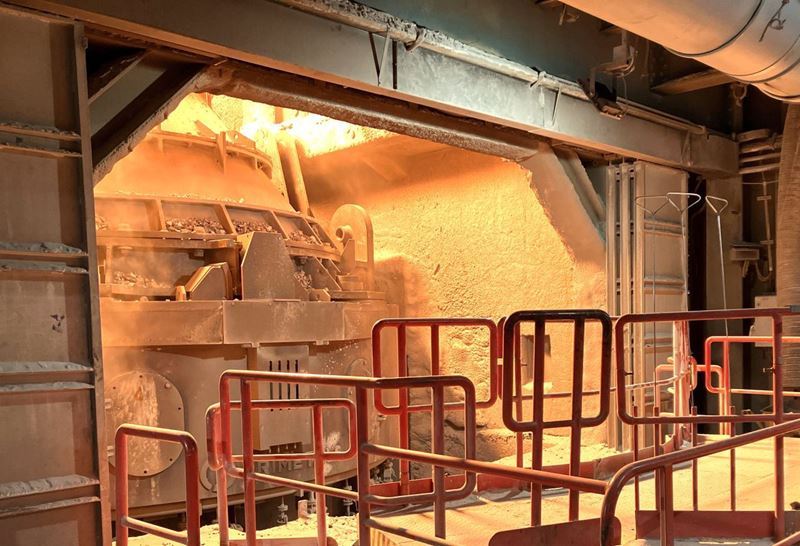

Primetals Technologies’ supply scope also included transfer cars, a semi-automatic ladle transfer crane, and expansion of the existing material handling system.

Aperam, active in stainless steel, electrical steel, alloy and specialty steel production, as well as recycling and renewable energy, serves customers in over 40 countries. The company has a total flat stainless and electrical steel production capacity of 2.5 million tons across Brazil and Europe. Major stainless steel production sites in Europe include Châtelet and Genk in Belgium and Gueugnon and Isbergues in France. The Genk plant produces hot and cold-rolled AISI 300 and 400 series grades in coil form. Its No. 1 AOD line was previously supplied by Primetals Technologies in 2002.

Comments

No comment yet.