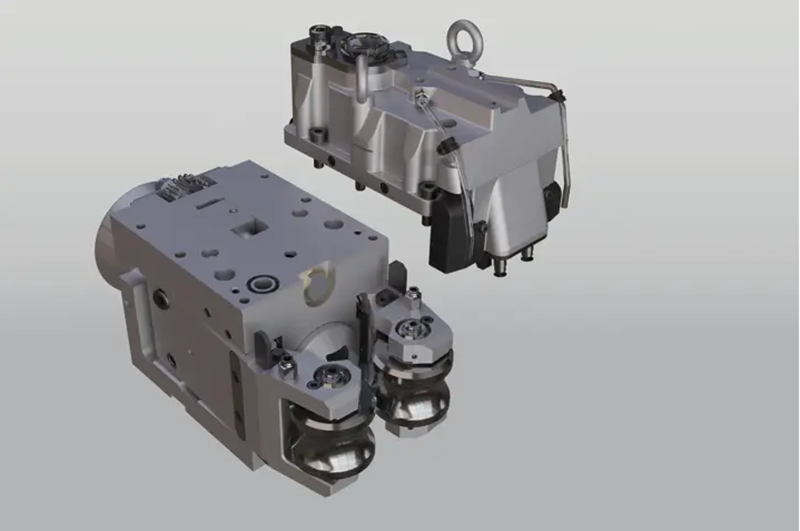

Based on the legacy of Morgan and Ashlow guide technology, this patented system combines robust mechanical design with intelligent sensing technology to enhance safety, efficiency, and overall mill performance.

The new system prevents alignment errors, scoring, and unplanned stoppages in bar and section rolling mills while improving dimensional accuracy and enabling predictive maintenance. Critical functions such as cross-section height measurement, guide alignment, bearing and roll condition, speed monitoring, and impact tendency analysis are digitized, allowing operators to monitor them remotely. Its built-in wireless communication feature enables operators to adjust and monitor the guides without entering high-risk areas.

Thanks to continuous cross-section height tracking, guide alignment monitoring, and internal condition diagnostics, the system can detect wear early and optimize guide settings to support consistent and reliable mill operation. Its modular design and multiple size options facilitate integration with digital platforms across the plant and ensure long-term durability.

Benefits highlighted by Primetals Technologies include enhanced safety through remote operation, increased productivity via continuous monitoring, improved product quality through accurate alignment and early wear detection, optimized maintenance planning for greater efficiency, and reduced operating costs.

One user said, “The guides we tested performed exceptionally well, and the program changes made on continuous mills were very beneficial. The most important point was that the guides prevented pebble build-up and reduced injury risk.”

The new Advanced Roll Guides stand out as a significant innovation aimed at improving safety, productivity, and quality in long rolling mills.

Comments

No comment yet.