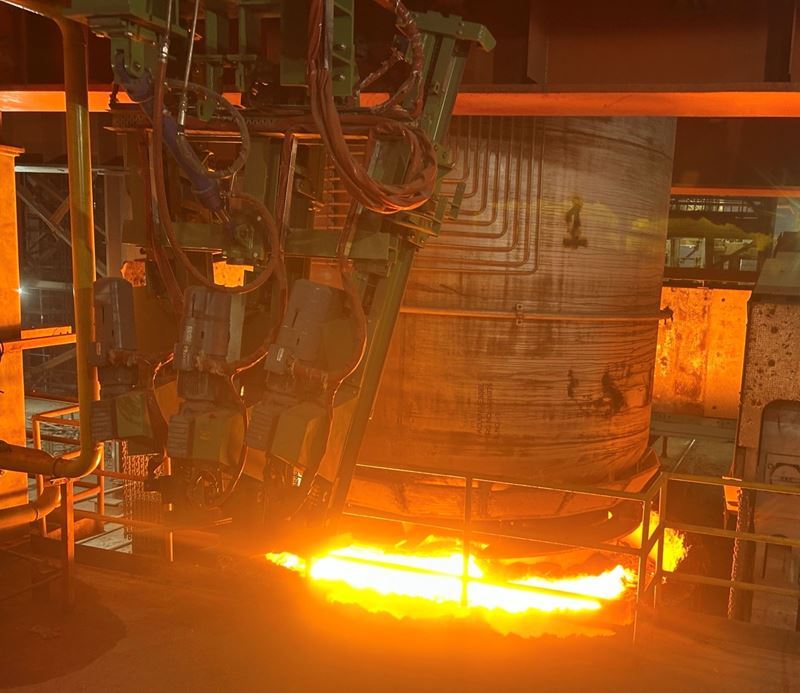

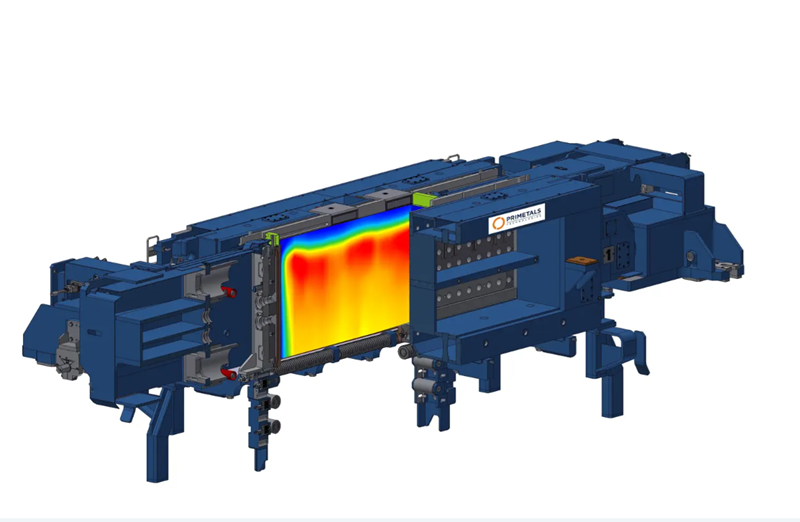

The new RH system introduces a notable innovation in secondary metallurgy, combining the RH ladle shaking system with the fast vessel exchange (FvE) technology in a single operational structure for the first time worldwide.

The commissioned plant enhances JVML’s capacity to produce high-quality steel grades for demanding sectors such as construction, infrastructure, manufacturing, automotive, and energy. The new RH configuration delivers higher process efficiency, stronger safety standards, and faster production flow compared with traditional models. The plant’s annual production capacity is around three million tons.

The RH vacuum process produces cleaner steel with superior mechanical properties. JVML’s new unit integrates a proven FvE system with a ladle shaker that allows controlled lifting and tilting of the ladle. This combination shortens vessel change times, extends tank life, and enables faster grade transitions, enhancing the plant’s strategic and operational flexibility.

The ergonomics and accessibility advantages of the ladle shaking machine, combined with the fast transfer capability of FvE technology, improve plant safety while reducing maintenance requirements. The FvE system shortens change cycles, minimizes downtime, and allows higher annual production without additional manpower.

Another key design element is the ferro-silicon (FeSi) bunker placed at the top, which increases alloy availability within the plant and prevents charging interruptions. This feature reduces processing times in electric steel production and improves both process stability and efficiency.

JVML Vice President Nikhil Agashe emphasized the unit’s importance for the company: “The 350-ton RH unit with fast vessel exchange represents a significant step change in our production capacity and quality flexibility. It integrates seamlessly into Vijayanagar Works steel plant 4, maximizes our operational efficiency, and enhances safety and maintenance ease. SMS group’s solution directly supports our goal of delivering higher-quality steel to our customers.”

SMS group Contract Manager Christina Godolt stated the significance of the technology: “Commissioning the world’s first 350-ton RH ladle shaking machine with FvE is a proud milestone for both SMS group and our partnership with JSW Steel. This technological breakthrough reinforces SMS group’s engineering leadership while delivering tangible benefits in plant efficiency, lifecycle costs, and safety.”

JSW Steel and SMS group previously installed the company’s first 350-ton RH unit at the Dolvi plant in 2023 and completed the second unit in 2024. Pleased with the performance of these plants, JSW Steel decided to equip all RH units at Vijayanagar Works with SMS group’s 350-ton ladle shaking system and FvE technology, further strengthening its strategic position in the Indian market.

Comments

No comment yet.