The Climate Law, which is at the forefront of these steps, initiates a multi-sectoral transformation process that will affect many sectors such as energy, industry and transportation. The iron and steel industry, which has a particularly high share in terms of carbon emissions, is at the center of this transformation.

Climate Law and Basic Regulations

With the Climate Law, Türkiye aims to comply with international obligations such as the Paris Climate Agreement, the European Green Deal and the EU's Carbon Border Adjustment Mechanism (CBAM). The law aims to reduce greenhouse gas emissions, promote clean and low-carbon technologies, strengthen adaptation to climate change and support green growth.

Reducing the carbon footprint of products and production processes is now a legal obligation. Industrial facilities will be covered by the Emissions Trading System (ETS), where they will be obliged to surrender allowances corresponding to their emissions. Under the ETS, businesses will be able to use carbon credits to reduce and offset their carbon emissions, but these credits must be certified by independent and accredited organizations.

Current Situation and Challenges in the Iron and Steel Industry

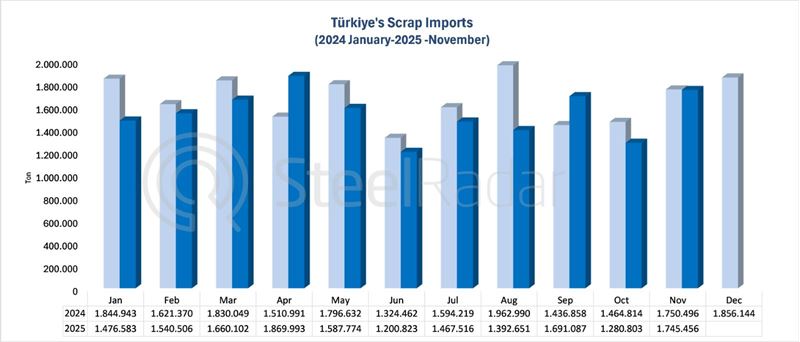

Approximately 75% of Türkiye's steel production is realized through the electric arc furnace (EAF) method. This technology has relatively low carbon emissions thanks to the use of scrap. On the other hand, the country's three integrated steel plants emit 2.2-2.4 tons of carbon dioxide per ton, close to European standards. Currently, however, indirect (scope 2) emissions under the ETS for electric arc furnace production are yet to be included. The European Union's plans to expand this scope may directly affect Turkish producers in the coming period.

Low-carbon technologies in iron and steel production (such as hydrogen steel production, carbon capture) are still under development and not widely used in Türkiye. It is likely to take years for these technologies to become widespread and commercially viable.

The law will require industrial facilities to obtain carbon certificates. Annual emission estimates will be made in line with production plans and these certificates will be purchased in the ETS market. Although free allowances will initially be provided, the scope and duration of this practice is not yet clear.

Renewable Energy and Financial Support Mechanisms

The industry is turning to renewable energy to reduce its carbon footprint. However, in Türkiye, the requirement for renewable energy investments to be made within the factory site creates major obstacles due to limited land and infrastructure problems. As a result, renewable energy investments are increasing in regions such as Konya, Çorum and Southeastern Anatolia, where production facilities usually find suitable land.

The Climate Law encourages climate-friendly investments by defining Türkiye Green Taxonomy. Through green bonds, sustainable funds and private sector-backed financing models, banking and capital markets are targeted to provide resources for low-carbon projects. However, the effectiveness and prevalence of these support mechanisms are critical for the sector.

Audit, Sanctions and Fines

Under the law, businesses operating without an emission permit will be suspended. Businesses that do not submit a greenhouse gas report will be fined between TRY 500 thousand and TRY 5 million. In the use, import and trade of substances that damage the ozone layer, fines of up to TRY 2.5 million and bans on hydrofluorocarbon control certificates for 3-6 months have been introduced. The authority for inspection and sanctions was given to the Climate Change Presidency.

International Competition and the Importance of CBAM

The European Union is trying to prevent carbon leakage by directly taxing the carbon costs of imported products with CBAM, which will enter into force in 2026. The fact that major producers such as China, India and the US are distant from these regulations complicates Türkiye's competitive position. For this reason, Türkiye needs to establish its own CBAM to avoid problems in exports and balance the carbon tax on imports.

An expert told SteelRadar that due to low profit margins in the iron and steel industry, it is inevitable that increasing carbon costs will be reflected on the final product. For example, if integrated steel plants emit 2 tons of carbon dioxide per ton and carbon prices are around EUR 75, production costs will increase significantly. This cost increase will be directly reflected in consumer prices.

Future of the Industry

The Turkish steel industry is in an advantageous position in terms of low-carbon production thanks to renewable energy investments and high scrap utilization rates. However, the requirement for carbon certificates, the CBAM and the EU's increasingly stringent regulations may weaken the sector's competitiveness.

In addition, the effective use of financing resources, the elimination of uncertainties in the carbon trading system and rapid adaptation to technological innovations stand out as key factors that will determine the future of the sector. The necessity of green transformation offers opportunities for the sector to remain sustainable and globally competitive in the long term.

An expert from the EU stated: "As you know, the EU's CBAM (Carbon Border Adjustment Mechanism) is now in place. In an economic structure where Türkiye is so integrated with the EU, it would be difficult to sustain exports without such a carbon pricing mechanism. In other words, Türkiye is launching this ETS not only to be “climate friendly” but also to avoid losing its competitiveness. Frankly, I see this as a very concrete example of the intersection of climate policy and trade strategy: CBAM is not just a European policy; it has become a tool to transform behavior in global markets. Particularly for developing countries, systems such as ETS are no longer just environmental, but financial and strategic imperatives. It opens many doors, from attracting green investment to reducing carbon risks."

Conclusion

The Climate Law initiates a mandatory and comprehensive transformation of Türkiye's steel industry. While existing advantages and technological infrastructure are the industry's lucky sides in this transformation process, international competition and the management of carbon costs will pose major challenges. It is now inevitable for businesses to develop innovative and sustainable solutions with government support and financing mechanisms.

Comments

No comment yet.