Borçelik: Türkiye’s Strategic Flat Steel Producer with Global Reach

Borçelik, a subsidiary of the Borusan Group, began operations in 1994 on a 240,000 square meter site in Gemlik, Bursa. The company continues its activities in partnership with ArcelorMittal, one of the world’s largest steel producers. With a workforce of 1,100, the facility produces approximately 1.5 million tons of flat steel annually, divided into three main product lines: cold-rolled steel, galvanized steel, and pickled hot-rolled steel.

Production is carried out in coils measuring up to 1.5 meters wide, 2 meters in height, and weighing between 15 and 20 tons. As a key supplier to Türkiye’s leading industrial companies, Borçelik provides raw materials to various sectors, including automotive, home appliances, radiators, and heating-cooling systems.

Borçelik General Manager Kerem Çakır emphasized the company’s strategic position for the Turkish industry. He noted that cold-rolled steel is used in radiators, refrigerators, and washing machines, while galvanized steel is primarily used for vehicle body panels in the automotive sector.

Çakır highlighted the continuous expansion of Borçelik’s product range with advanced steel grades. The company produces high value-added products such as commercial, deep-drawing, dual-phase, oven-hardenable, rephosphorized, and HSLA steels to maintain high quality standards.

Regarding production capacity, Çakır stated:"With our current annual flat steel production capacity of approximately 1.5 million tons, we are among Türkiye’s highest-quality producers. Of this, 600,000 tons are cold-rolled steel and 900,000 tons are galvanized steel. Combined with the 500,000-ton capacity of our Kerim Çelik steel service center, we manage a total processing and delivery volume approaching 2 million tons."

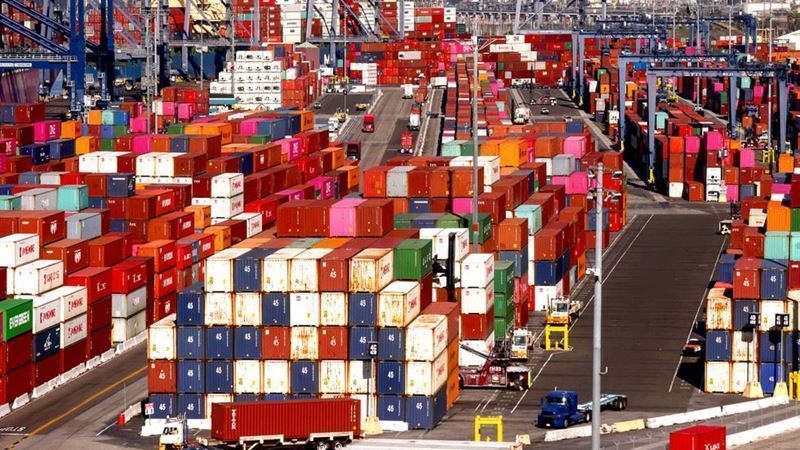

Çakır noted that the company exports directly to 36 countries, primarily targeting the European Union, the Balkans, and North America. He added that about 75% of the sectors they supply are export-oriented, meaning Borçelik’s products reach even wider markets through the final products.

When considering both direct and indirect exports, approximately 80% of Borçelik’s steel reaches global markets, making the company one of the region’s flat steel suppliers with the broadest international reach.

Çakır emphasized that Borçelik’s core mission is to support industrial companies engaged in value-added production. He noted that Borçelik’s steel is used in 9 out of every 10 cars produced in Türkiye and in all major home appliances.

He also highlighted the company’s effective use of artificial intelligence (AI) in production processes. Çakır explained that technology is positioned as a tool to empower employees, rather than replace them, with AI applications focused on improving efficiency, ensuring consistent quality, optimizing energy and resource use, and enhancing workplace safety.

Borçelik’s future strategy is built on three main pillars: quality, digitalization, and green transformation. Investments to modernize the galvanized steel lines are ongoing, alongside AI-supported quality control and automation projects.

Highlighting the importance of green transformation, Çakır stated that investments in solar and wind power plants are planned, and efforts to improve energy efficiency and use low-emission raw materials are continuing. He also noted that social initiatives related to education, employment, and equal opportunities are an essential part of sustainability.

Sourced by: Anadolu Agency (AA)

Comments

No comment yet.