As part of this initiative, the company selected Primetals Technologies to supply Mold Expert Fiber systems. Through this collaboration, HKM aims to enhance quality, efficiency, and reliability across its production processes.

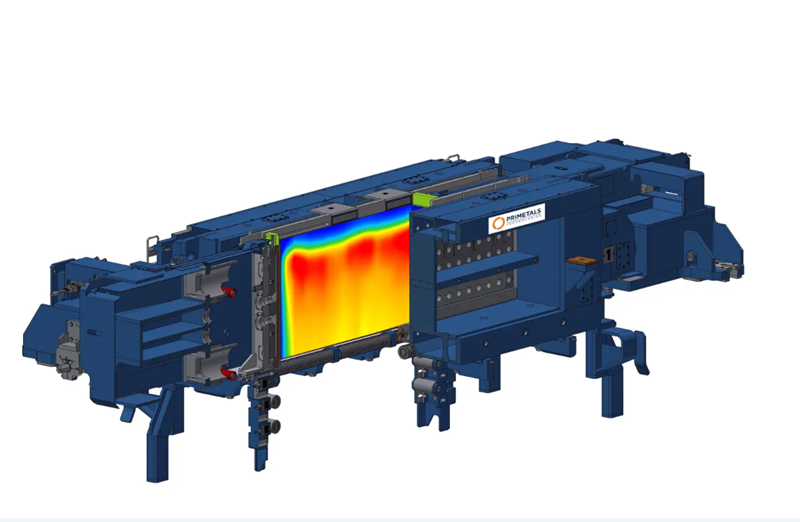

The Mold Expert Fiber system offers advanced mold visualization technology, enabling highly precise monitoring of critical areas that determine slab surface quality. The system can detect issues that may negatively affect production—such as sticking, cold spots, and longitudinal cracks—at an early stage. It also allows better control of the mold-filling process during casting start-up and supports product quality by reducing meniscus asymmetry.

Using fiber-optic–based temperature measurement technology, the system can collect data from thousands of measurement points in each mold, with the option to increase this number to more than 10,000 if required. Compared with conventional systems that rely on a limited number of thermocouples, it provides far more detailed and real-time feedback on meniscus shape, mold powder behavior, and taper accuracy. This enables operators to monitor the casting process more closely and respond quickly and accurately.

The core objective of Mold Expert Fiber is to deliver previously unavailable insights into the production process by precisely measuring the meniscus profile across the mold width and providing detailed data on liquid steel flow within the mold. The system alerts operators at the earliest stage to potential mold breakouts and casting problems, improving operational safety and helping to reduce downtime.

HKM has an annual liquid steel production capacity of around four million tonnes and specializes in slab and bloom casting. The company employs approximately 3,000 people at its integrated Duisburg plant, producing intermediate products for the processing industry and offering a broad portfolio of more than 2,000 steel grades. HKM operates as a joint venture between Salzgitter, thyssenkrupp, and Vallourec.

The agreement with Primetals Technologies is expected to support the development of advanced steel grades at HKM, strengthen digitalization in production processes, and enhance the company’s competitiveness. With the new system, HKM aims to achieve higher quality standards in continuous casting technology.

Comments

No comment yet.