Under the project led by DB InfraGO, the green steel rails will be installed in North Rhine-Westphalia, Rhineland-Palatinate, and Saarland, covering a total length of approximately 22 kilometres.

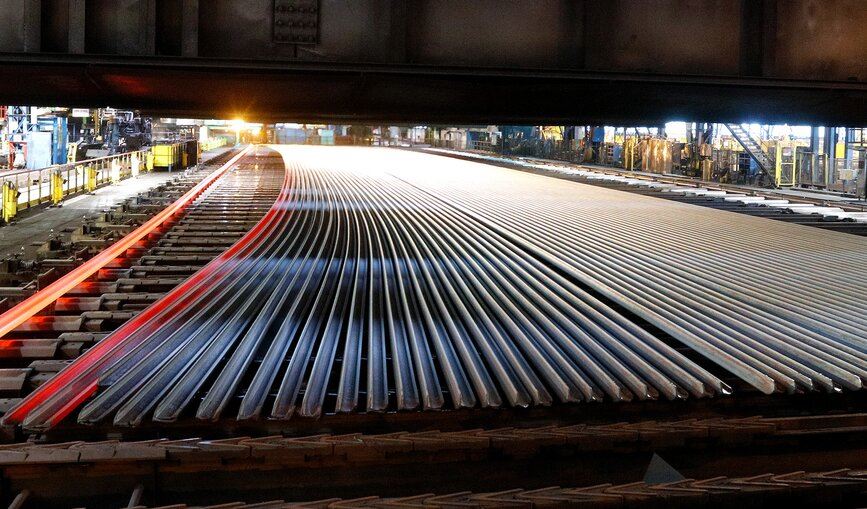

The cooperation marks an important step toward sustainable supply chains and circular economy practices in the rail industry. The green steel supplied by Saarstahl Rail is produced at the Saarstahl Ascoval plant in France, which uses electric arc furnace (EAF) technology instead of traditional blast furnaces. This process enables the production of new steel from scrap and old rails, cutting greenhouse gas emissions by up to 70% compared to conventional methods. The use of 1.000 tonnes of green steel is expected to save around 1.800 tonnes of CO₂.

As part of its plan to achieve full carbon neutrality by 2040, Deutsche Bahn is increasingly integrating low-emission materials into its infrastructure projects. The company notes that about 50% of its Scope 3 emissions, indirect emissions from upstream and downstream activities, stem from construction operations, underscoring the need for more green steel and green concrete solutions.

DB’s environmental transformation strategy focuses on five key areas: climate resilience, climate protection, resource efficiency, environmental protection, and noise reduction. Through such pilot projects, the company aims to further reduce the carbon footprint of rail construction and strengthen the sustainability of its supply chain.

Comments

No comment yet.