One of the key stages of the project was the replacement of the old DC motors with three-phase AC motors. This upgrade included advanced variable-frequency drive systems operating with active front ends and new transformers. The new drive system installed by SMS group delivers 20% higher torque compared with the mill’s original design capacity, restoring GARMCO’s hot rolling operations to full capability. As a result, the facility has achieved a modern, future-ready configuration capable of supporting R&D activities in aluminum hot rolling.

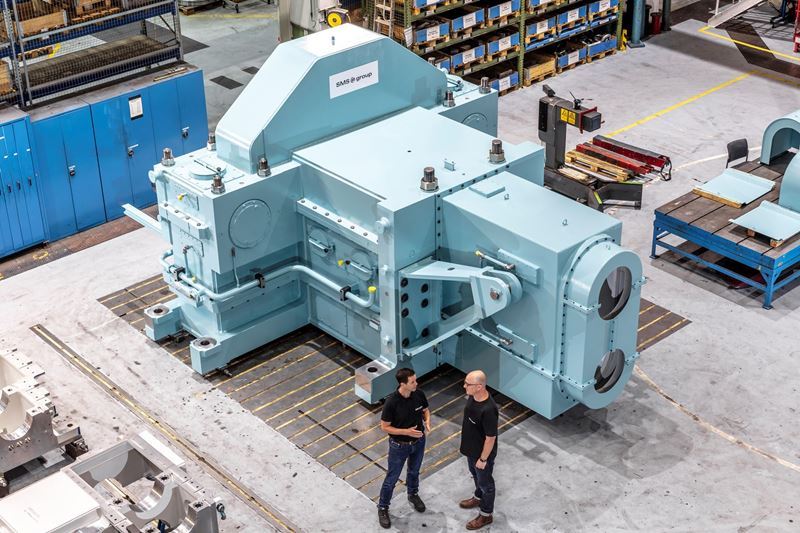

At the core of the modernization is SMS group’s state-of-the-art twin-motor drivetrain. The system consists of two electric motors rated at 2,150 kW each, two SMS heavy-duty torque spindles, and a specially designed gearbox integrating all components. This design—enabled by SMS group’s advanced gear engineering—reduces investment costs, saves space, and provides high operational redundancy.

In addition to the two main motors, SMS group also supplied next-generation control and drive components. These include X-Pact® Drive low-voltage frequency converters for the entry and exit coilers, medium-voltage converters operating in load-sharing mode, and the required transformers. This equipment is engineered to meet the demanding performance requirements of GARMCO’s extensive product range, including aluminum coils, tread plates, slit coils, and foil.

Ebrahim Khalil, GARMCO’s Chief Operations Officer, highlighted the significance of the modernization, stating: “The completion of this project demonstrates our commitment to maintaining world-class operational quality. SMS group’s expertise and advanced technological solutions have provided us with greater reliability and efficiency in our hot rolling operations.”

Although SMS group’s relationship with GARMCO began years ago with technical services, this project stands out as the most comprehensive collaboration to date. With the successful completion of the modernization, GARMCO’s hot rolling mill is now well positioned to ensure the sustainable production of high-quality aluminum products for its global customer base.

Comments

No comment yet.