Could you tell us about Rivotto’s founding motivation? How did the idea emerge to address the long-standing emission challenges of energy intensive industries through a more scientific and practically applicable approach? Which needs, observations, or industrial gaps led you to design the Nx25 technology?

Rivotto CEO Steven Shallenberger;

Rivotto was formed to address a persistent challenge in heavy industry: how to improve combustion efficiency and reduce emissions without requiring major equipment replacement or process redesign.

Nx25 emerged from this focus as a physics-based combustion enhancement that improves how fuel burns inside existing furnaces and boilers. Rather than replacing assets or changing fuel chemistry, Nx25 increases thermal efficiency within the combustion zone itself.

The result is a practical upgrade that can be deployed quickly, delivers measurable fuel and CO₂ reductions, and fits within current operational and regulatory frameworks.

The steel industry is under unprecedented pressure due to EU ETS costs, upcoming CBAM obligations, and rising energy prices. In your view, what are the most critical bottlenecks the sector is facing? While hydrogen transition, EAF modernization, or carbon-capture systems appear theoretically possible, why are they practically out of reach for most facilities?

The steel sector sits at the heart of global decarbonization. Producers face rising competition, tightening regulations, and an urgent need to reduce CO₂ — all while operating on narrow margins.

Key bottlenecks include:

• Emissions costs driven by EU ETS and CBAM obligations

• High upfront cost and complexity of hydrogen and CCUS technologies

• Long project timelines and permitting uncertainty for large capital projects

• Capital funding and/or Electricity grid limitations that slow large-scale EAF transitions

• Scrap availability, purity, and quality constraints limiting full transition to secondary (EAF-based) steel

• Price competitiveness challenges for EAF steel in markets with tight or inconsistent scrap supply

Where Nx25 Fits

Nx25 offers real, reportable CO₂ and fuel reductions using the infrastructure that already exists — bridging the gap between today’s operating realities and tomorrow’s long-term transition technologies.

In your opinion, which types of steel producers can benefit the most from Rivotto’s solution? Considering factors such as production technology, energy model, carbon intensity, regulatory pressure, or cost structure, how would you define the market segment where Nx25 delivers the highest impact? Additionally, how do you assess the level of interest in emission-reduction solutions among producers in this segment?

Nx25 delivers the highest value in steel operations where fuel efficiency and emissions costs are material operating concerns. Typical candidates include:

• Integrated steel plants operating blast furnaces and BOF systems

• Sites with high coal or coke consumption

• Producers exposed to EU ETS or CBAM compliance costs

• Operations with limited appetite for long shutdowns or large capital projects

Interest is strongest where producers require measurable emissions reductions within current compliance cycles, rather than over multi-decade transition timelines.

“If your plant burns coal and carries carbon cost exposure, Nx25 is designed for you.”

Nx25 is described as “bringing physics into the combustion chamber,” which is quite a striking definition. What exactly does this solution modify or optimize within combustion processes? Could you explain—technically, yet in a clear and accessible way—the improvements Nx25 brings in terms of heat management, particle behavior, combustion efficiency, or reaction dynamics?

Nx25 is a physics-based combustion upgrade delivered as a carbon-free, liquid fuel. It is introduced directly into the combustion zone via injection or atomized fogging.

Within the flame, Nx25 serves as a new fuel, releasing high-energy particles that both add energy and reshape combustion dynamics of the primary fuel (e.g., coal) to drive a more complete and efficient burn.

Nx25 does not change the chemical content of the primary fuel (e.g., coal). It improves how that fuel is burned — a critical distinction for regulatory compatibility and plant risk management.

You state that Rivotto’s solution can reduce CO₂ emissions at a typical blast furnace by around 10%, and lower fuel costs by 5–10%. What is the core mechanism behind these results? Does its performance vary depending on furnace type or fuel quality?

Nx25 has been evaluated through controlled testing at the University of North Dakota’s Energy & Environmental Research Center (EERC) as well as in Rivotto’s internal laboratory programs. Results across these studies show consistent efficiency improvements.

Observed outcomes include:

• 6–14% reduction in coal consumption

• Corresponding 6–14% reduction in direct CO₂ emissions

• Up to 30% reduction in NOₓ emissions

• Measured reductions in select additional pollutants

Because Nx25 contains no carbon and does not change fuel chemistry, reductions in coal use translate directly into claimable CO₂ reductions under existing ETS and CBAM methodologies.

Nx25 is notable for its exceptionally short installation timeframe. What factors enable such rapid integration? Additionally, can comparable performance be achieved in industries beyond the steel sector?

Nx25 is designed for integration into operating steel plants with minimal disruption.

Key requirements include access to a suitable injection point, a high-temperature combustion zone, and basic process data for tuning. Nx25 has applicability across blast furnaces, BOF systems, and other high-temperature industrial combustion environments.

How are the emission reductions achieved through Nx25 recognized under the EU ETS and CBAM frameworks? Could you elaborate on how the verification process is structured and implemented?

Nx25 is fully compatible with Regulation (EU) 2018/2066. Plants using standard mass-balance methods for emissions reporting do not need to change their monitoring plans or methodologies to integrate Nx25.

Reductions are captured through the same core variables — fuel quantity, carbon content, and combustion completeness — ensuring that Nx25 fits seamlessly into existing compliance workflows. Where CEMS monitoring is present, operators may also quantify additional real-time efficiency gains.

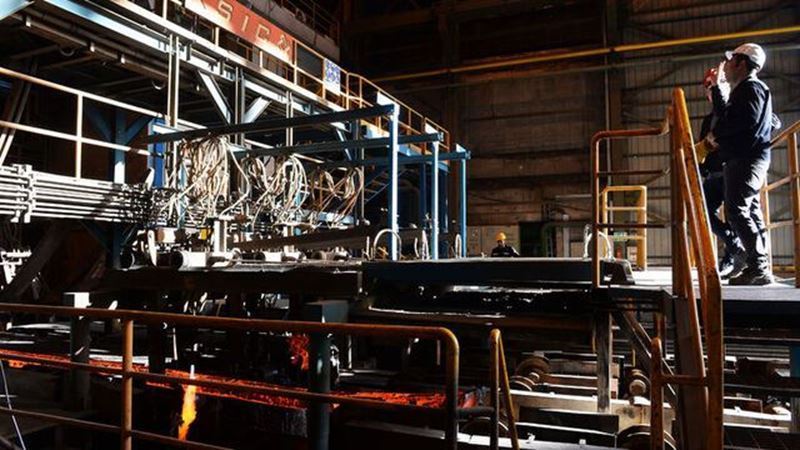

.jpg)

Steel producers face a growing need for Nx25 under certain conditions. What indicators signal that this need has materialized?

Rivotto Senior Advisor Dean Duncan:

Nx25 typically comes into play under the following conditions:

-

When carbon costs begin to exert pressure on profitability

-

When energy prices become increasingly volatile and unpredictable

-

When large-scale transformation or decarbonization projects are postponed

-

When improvements are required without interrupting production

For a facility consuming approximately one million tons of coal per year, Nx25 can represent savings of several million euros.

How do you envision Rivotto’s position over the next three to five years? What key message would you like to communicate to the industry?

Rivotto’s focus is on accelerating emissions reductions in hard-to-abate sectors where existing assets will remain in service for decades. Nx25 is positioned as a near-term efficiency solution that complements, rather than competes with, longer-term transition technologies such as hydrogen and CCUS.

The core message is straightforward: meaningful emissions reductions can begin now, using the systems already in place.

A Simple Message to Industry

"You don’t have to wait for hydrogen or CCUS to start decarbonizing. With Nx25, you can reduce emissions now — inside the system you already have."

Comments

No comment yet.