Helioroof®, ready-to-install all-in-one modules, can generate up to 2.1 kWp per module. Panels can be custom-made up to 12 meters in length, making them a world record in terms of both size and power.

A low-carbon solution for renewable energy

Developed by ArcelorMittal Building Solutions, Helioroof® is seen as a strong step toward sustainable construction. Weighing only half as much as traditional roof systems with integrated solar panels, it also has a 25% lower carbon footprint compared to conventional insulated steel roofs.

The product is manufactured using ArcelorMittal’s XCarb® steel, made from recycled and renewable sources. The insulation layer placed between two steel sheets not only ensures thermal efficiency but also enables high energy generation through direct integration of solar panels into the top steel layer. All components are assembled at the Contrisson facility.

Patented innovation developed with European expertise

The Helioroof® project was developed through collaboration between ArcelorMittal Building Solutions’ R&D teams and CRM Group, a Belgium-based research organization. With CRM Group’s expertise in metallic materials and industrial innovation, both the design and industrial production processes were shaped according to the highest quality standards.

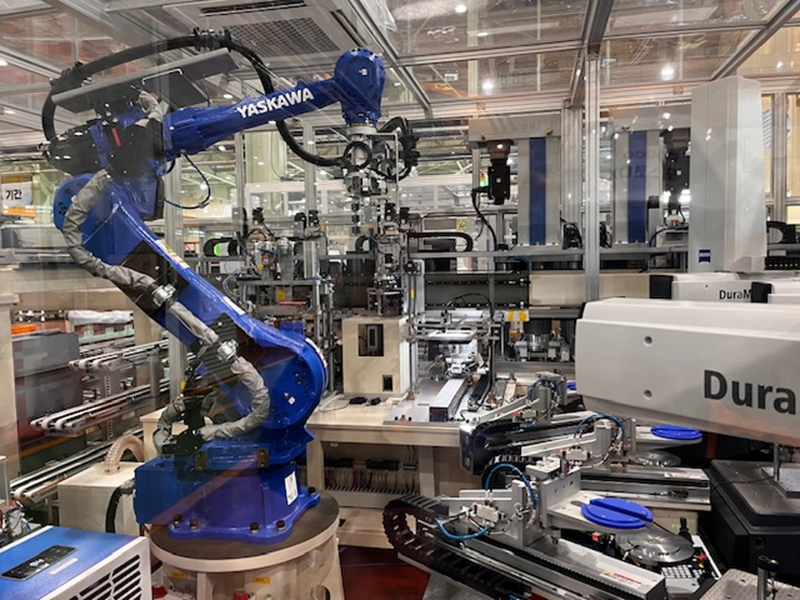

The production line, specifically designed for the Contrisson facility, stands out for its high automation and quality monitoring. ArcelorMittal teams work under “gray room” conditions to preserve the integrity of the solar panels, integrating specialized expertise from the solar energy sector into the production process.

Comments

No comment yet.